Proctor test for soil compaction

This article represents proctor test which used to determine the maximum dry unit weight of compacted soils that is usually used for knowing the specifications of field compaction. This method is known as the modified proctor compaction test. In this experiment, 5 different samples of soil passing sieve #4 where compacted and prepared using the modified proctor. The samples were different in their water content. After the samples where oven dried and all measurements were taken, the relations between the dry unit weight and the water content, and the zero-air-unit weight and the water content were plotted. The maximum dry unit weight of compaction, and the optimum moisture content were then determined.

|

| Soil compaction |

Aim of the experiment:

The aim of this experiment is to find the maximum dry unit weight of compacted soils passing sieve#4, and its optimum water content. The relation between the dry unit weight and the water content is also to be plotted and studied.Theory:

In compaction test, dry unit weight (γd) is used as expression for degree of compaction. Dry soil can be compacted when a suitable amount of water is added to that soil during compaction, which acts as softening (lubricating) agent between soil particles, as A result, particles slip over each other and so be densely packed particle. In the initial stages of compaction as water content increase, the dry unit weight increase too. If the moist unit weight (γ) is equal dry unit weight at the moisture content = 0, then the dry unit weight at moisture content w1 can be calculated by:

γd (w = w1) = γd (w = 0) + ∆ γd.

To achieved a good result of compaction, the maximum dry unit weight is attained which occurs at the optimum moisture content. For this purpose, the Proctor Compaction Test must be done. In past, Standard Proctor Test is used, by improvement of compaction rollers it is modified to better represent of field conditions and use the Modified Proctor Test.

γd can be computed in terms of the wet unit weight, γwet , and the moisture content w% by this equation:

The moisture content (w %) can be determined in the modified proctor test as follows :

Where:

W= weight of moist sample.

W1= weight of oven dry sample.

And the wet unit weight determined using this equation:

Where:

W2= weight of the moist compacted soil + weight of the mold

W3=weight of mold.

Volume of modified mold= (1/13.33) ft³

The point when there is no voids between the particles of the soil for a given moisture content (the soil is fully compacted) can be defined as the maximum theoretical dry unit weight of compacted soil (the degree of saturation = 100%) , so the zero air void unit weight is given from the following equation:

Where:

γzav= zero-air-void unit weight.

γw= unit weight of water.

w= moisture content.

Gs= specific gravity of soil solids.

A plot of several values of w% and their corresponding values of γd can be used to determine the value of both the maximum dry unit weight ( γd max ) and its optimum moisture content ( w opt ) . γzav versus w% can be plotted on the same graph. For modified compaction test, the energy per unit volume of compaction (E) can be determined as follows:

E= [number of layer*number of blows*weight of hummer*height of drop] /volume of hummer.

If the compaction effort per unit volume of soil is changed, the moisture- unit weight curve will change, as the amount of the compaction energy increased, the curves shift upwards and to the left so that the maximum dry density increases and the corresponding optimum water content decreases.

The Modified Proctor test, ASTM D1557 / AASHTO T180, uses mould of 6 inches in diameter and holding 1/13.333 ft³, but uses a 10 lb. hammer falling through 18 inches, with 56 blows on each of five lifts.

Equipment:

- Modified proctor hummer

- Balance

- Large pan

- Jack

- Moisture cans

- Oil

- Drying’ oven

- Sieves: ¾ in

- Steel edge

- Compaction mold and its hammer (see the following table)

Table-1: Requirements for using the modified proctor test

| Volume (ft³) | 1/13.33 |

| Height (in) | 4.58 |

| Diameter (in) | 6 |

| Weight of hammer (Ib) | 10 |

| Height of drop of hammer (in) | 18 |

| number of layers of soil | 5 |

| Number of blows per layer | 56 |

| Test on soil fraction passing sieve | ¾’’ |

Procedure:

- Ready sample was taken and sieved on sieve ¾ in to obtain about 6 kg of the passing soil.

- About (10 ml) water was added and mixed well.

- The weight of the proctor mold and its base were determined.

- The extinction is attached to the top of the mold and then oiled.

- The moist soil is poured into the mold in 5 almost equal layers. Then each layer should be compacted by the hummer for 56 blows.

- After the each five layer were compacted, the extension is removed, and using a straight edge the excess soil is removed.

- Using #4 in sieve, any hole in the top surface is filled.

- The weight of the proctor mold, base and the compacted soil were determined

- Using a jack, the compacted soil is removed from the mold.

- A moisture can is weighted and then used to take a sample form the core of the compacted soil, and then it’s placed in the oven for 24 hours and then weighted again.

- The mold is cleaned and oiled and the steps (4 – 10) are repeated for another four times.

Data and calculations:

Table-2: Original data and results

| TRIAL NUMBER | |||||

| 1 | 2 | 3 | 4 | 5 | |

| Weight of mold, W1 (g) | 4997 | 4997 | 4997 | 4997 | 4997 |

| Volume of the mold (cm³) | 2124 | 2124 | 2124 | 2124 | 2124 |

| Weight of mold + moist soil , W2 (g) | 9436 | 9524 | 9584 | 10030 | 9999 |

| Weight of moist Soil = W2-W1 (g) | 4439 | 4527 | 4587 | 5033 | 5002 |

| Moist unit weight, γ (g/cm³) | 2.09 | 2.13 | 2.16 | 2.37 | 2.35 |

| Moisture can number | 87 | 69 | 76 | 74 | 99 |

| Weight of moisture Can, W3 (g) | 28.5 | 28.1 | 28.0 | 27.8 | 28.5 |

| Mass of can + moisture soil, W4 (g) | 276.7 | 291.6 | 230.9 | 233.3 | 232.0 |

| Mass of can + dry soil, W5 (g) | 272.8 | 284.9 | 222.7 | 223.4 | 218.3 |

| Water content %W = ((W4-W5)/(W5-W3))*100% | 1.60 | 2.60 | 4.21 | 5.06 | 7.2 |

| Dry unit weight of compaction, γd (g/cm³) | 2.06 | 2.08 | 2.07 | 2.26 | 2.19 |

Sample calculation:

Moist unit weight (ү) = ((9436-4997)/(2124)) = 2.09 g/cm³

Ww = W4 – W5 = 276.7 – 272.8 = 3.9 g

Ws = W5 – W3 = 272.8 – 28.5 = 244.3 g

Water content (W%) = ((276.7-272.8) / (272.8-28.50))*100% = 1.60

Dry unit weight γd = 2.09 / (1 + 0.016)) = 2.06 g/cm³

Energy = (56*5*10*1.5)/(1/13.13) = 55146 ib.ft/ft³

|

| Fig.1- Dry unit weight Vs water content |

As the above figure shows, the maximum dry unit weight is-approximately equal to 2.26 g /cm3 which is corresponding to the OMC ( optimum water content ) which is-approximately equal to 5.06%

Table-3: Corresponding values

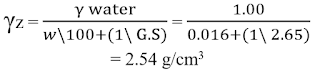

| Trial No. | Water content | γz (g/cm³) |

| 1 | 1.60 | 2.54 |

| 2 | 2.60 | 2.48 |

| 3 | 4.21 | 2.38 |

| 4 | 5.02 | 2.34 |

| 5 | 7.2 | 2.22 |

sample calculation for γzav:

The following figure shows the relation between γzav and the water content, see Fig.2

|

| Fig.2 -Water content (W%) Vs. γ zav |

Results and conclusion:

As it is noticed from table (2),the maximum dry unit weight increases until it reaches a maximum value (corresponding to the peak in figure = 2.26 g /cm3 ) then it start to decrease. This is because the soil voids initially are partially filled with water, and the remained are filled with air. During the experiment and as more water is added, the dry unit weight of compaction increases and the efficiency of the compaction process increases due to the effect of water which is acting as a lubricating agent, and break the inter-molecular bonds, the void spaces become smaller, and the amount of air in the voids decrease ( the degree of saturation increases) as water replace the air in the voids . After a certain amount of water is added ( which is OMC =5.05%) , the water takes up the spaces that would have been occupied by the solid particles, which results in a decrease in the dry unit weight and in efficiency of compaction.The left side of the curve in figure(1) is the dry side corresponding to decreasing dry unit weight. Whereas the right side is referred to as the wet side which is corresponding to decreasing dry unit weight.

It is always preferred to get values of max dry unit weight which is corresponding to the OMC to get relative degree of compaction (R=1) but , it is difficult so, it is preferred to be in the dry side over being at the wet side (more controllable).

As shown from table (3), the maximum compaction when the soil is fully compacted and there is no voids between the particles is the point where theoretical maximum dry unit weight is obtained (the degree of saturation(S) = 100%)

For figure (2) which shows the linear relation of γzav with moisture content. The line of zero air void is always located to the right of the curve of ( γdry Vs. w%), and will never intersect it.

In conclusion , in order to improve the engineering properties if a soil , it is required for earth work to achieve a compacted field dry unit weight of 90% to 95% of the maximum dry unit weight from laboratory by modified proctor test.

I generally want quality content and I found that in your post. The information you have shared about proctor test for soil compaction is beneficial and significant for us. Keep sharing these kinds of articles here. Thank you. Parking Lot Paving

ReplyDeleteStriking dispatch! I'm undoubtedly getting reasonable to over this data, is truly genial my amigo. In like way acclaimed blog here among beast levels of the rich data you secure. Hold up the obliging joint effort you are doing here. dumpster rental boca raton

ReplyDelete"Excavation often requires adaptation to changing conditions and unforeseen challenges." Land clearing Hobart

ReplyDelete