Workability test for fresh concrete: Concrete slump test, compacting factor and Vee-Bee test

The workability tests is divided into two steps, the first one include tests on fresh concrete such as concrete slump test, Compacting factor of concrete test and concrete Vee-Bee test which we carried out in laboratory in this experiment, and the second one is tests on hardened concrete which include destructive and non-destructive tests.

Workability is an important property that give us a clear picture about compatibility, Concrete may be considered as composed of four basic separate ingredients: cement, coarse aggregates, fine aggregates (including sand), and water. The aim is to produce the most economical combinations of concrete materials that satisfies the performance and specifications which are workability, durability, and strength.

|

| Fresh concrete pouring |

Objectives

The aim of this experiment is to measure the workability of fresh concrete for different water-cement ratios and to determine the effect of water content on the workability of concrete by measuring the concrete slump test, concrete Vee-Bee test, and the compaction factor of concrete test. The ratios used in this experiment is 0.5,0.6,0.7 respectively.Theory

Unfortunately, there is no acceptable test which will measure directly the workability. But there are methods give a measure of workability which is applicable only with reference to the particular method.

Concrete slump test

Concrete slump test is the most well-known used test method to characterize the workability of concrete. It is inexpensive and we can do it in job site to determine as fast as possible whether a concrete is accepted or not. The apparatus of concrete slump test consists of a mould in the shape of frustum with a base diameter of 200 mm, a top diameter of 100 mm, and a height of 300 mm. The cone is filled with concrete and then it is lifted vertically upward to measure the change in height of the concrete.

There are four slump shapes: true slump, shear slump, zero and collapse slumps. Each of these has a specific indication about the workability. The preferred shape is the true slump where the concrete remains intact and retains a symmetric shape, the shear slump where the top half of the cone shears off and slips sideways down an inclined plane & the slump from sideout 25–50mm. Zero and collapse are the least preferred and indicate unworkable concrete.

The preferred shape is the true slump as we said, a shear slump is a similar kind, but the test should be repeated in order to get a true slump. If a collapse slump occurs, either the mix is too wet, or it would be because of the design of the mix.

Concrete slump test is the most well-known used test method to characterize the workability of concrete. It is inexpensive and we can do it in job site to determine as fast as possible whether a concrete is accepted or not. The apparatus of concrete slump test consists of a mould in the shape of frustum with a base diameter of 200 mm, a top diameter of 100 mm, and a height of 300 mm. The cone is filled with concrete and then it is lifted vertically upward to measure the change in height of the concrete.

There are four slump shapes: true slump, shear slump, zero and collapse slumps. Each of these has a specific indication about the workability. The preferred shape is the true slump where the concrete remains intact and retains a symmetric shape, the shear slump where the top half of the cone shears off and slips sideways down an inclined plane & the slump from sideout 25–50mm. Zero and collapse are the least preferred and indicate unworkable concrete.

The preferred shape is the true slump as we said, a shear slump is a similar kind, but the test should be repeated in order to get a true slump. If a collapse slump occurs, either the mix is too wet, or it would be because of the design of the mix.

Concrete Vee-Bee test

The Vee-Bee apparatus consists of a vibrating table, a cylindrical pan, a slump cone, and a plastic dish attached to a free moving rod reference. It measures the remolding ability of concrete under vibration. The test results reflect the amount of energy required to remold a quantity of concrete under a given vibration condition. In the test as the Vee-Bee table is started the times for the concrete to remold from the slump cone shape to the shape of the outer cylindrical container is recorded as a measure of consistency.The compacting Factor of concrete test

It is another way of measuring the workability of concrete,the compaction factor test measures the degree of compaction resulting from the application of standard amount of work. The apparatus of the test consist of rigid frame that supports tow conical hoppers vertically aligned above each other and mounted above a cylinder. And the test is about recording the mass of the partially compacted concrete and the mass of the fully compacted concrete in the same cylinder.

The mass of the partially compacted concrete is measured before putting the sample on the hoppers, and the fully compacted concrete mass measured after putting it on the hoppers.And the compacting factor is defined as the ratio of the partially compacted to fully compacted mass.

Tools and instruments

- Weighing balance with capacity up to 100 Kg.

- Concrete mixer.

- Measuring cylinder of capacity 1 L.

- Water Buckets.

- Slump cone.

- Vee-Bee testing machine.

- Cement.

- Sand.

- Concrete.

- Aggregates.

- Steel tamping rod 16 mm diameter.

- Lubricating oil and brush.

- molds in different shapes (large cubes-15*15*15, small cubes - 10*10*10, cylindrical moulds, and elongated moulds).

- Vibrating machine (vibrator).

- Compacting factor apparatus.

- Shovel and trowels.

Procedure

The following procedure was repeated 3 times with different w/c ratios:

1. Preparing the sample:

- The correct amounts of sand, cement and aggregates were weighed.

- The correct volume of water was measured.

- Sand, cement, aggregates and water were mixed in the concrete mixer until a homogeneous mixture was formed; the mixture was then poured out.

2. Concrete slump test:

- The slump cone interior was lubricated with oil, and placed on a nylon bag on horizontal floor.

- The mold was filled with fresh concrete on three layers, each about 1/3 the height of the mold and each was tamped 25 times with the tamping rod.

- The surface was flattened with a trowel to remove the excess.

- The cone was removed horizontally and slowly and placed upside down near the sample with a tamping rod on top of it.

- The slump was measured and recorded in mm.

3. Compaction factor of concrete test:

- The cylinder of the compaction factor apparatus was weighted.

- The concrete was inserted in the top hoper of the compaction factor apparatus with the trap-doors closed.

- The trap-doors were opened until the concrete fills the cylinder.

- The surface was leveled and the excess concrete removed.

- The cylinder was weighted; the partially compacted weight was recorded.

- The cylinder was emptied and then refilled, this time with three layers, each damped on the vibrator until no air bubbles are seen, and then reweighed; this is the fully compacted weight.

4. Concrete V.B test:

- The slump cone was filled inside the V.B cylinder on three layers each tamped 25 times, and the surface was leveled with a trowel.

- The slump cone was removed slowly and vertically, and the plastic disc was placed on top of it.

- The vibrator was started at the same time the stop watch was started. When the conical shape fully transformed into a cylindrical shape, the stop watch was turned off. The measured time is the V.B time in seconds.

5. Preparing the molds:

Molds of different shapes and sizes were filled with fresh concrete at several layers (2 or 3 depending on the mold). Each layer was tamped either using the tamping rod or on the electrical vibrator. The surface was then leveled by removing the excess concrete with a trowel.Data and calculations

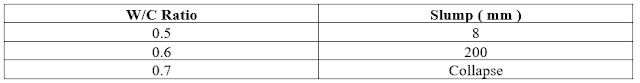

Slump test :Table-1: slump test

Compacting factor test:

Table-2: Compacting factor test experiment

Sample

calculation for W/C 0.6:

Partially

compacted weight = 17.00

Fully compacted

weight = 17.20

compacting factor = 17/17.2 = 0.988

Table-3: V.B test

Results and Conclusion

Results can be summarized in the following table:

Table-4: Results that have been obtained from the tests

Table -5: Classification of the concrete mixes prepared in the lab:

According to this table, the following is concluded:

- The mix with w/c ratio 0.5 is classified as low workable according to its slump value and V.B time.

- The level of workability for the mix with w/c ratio 0.6 is approximately high on both slump and V.B ranges. The high workability of this mix makes it suitable for some projects and unsuitable for others.

- The mix with w/c ratio 0.7 is unclassified which indicates that it is probably unsuitable for any civil engineering project.

Engineering use

Knowing the workability of concrete is important to know whether or not it is suitable for an engineering project. All three tests are vital, but the concrete slump test is the most significant since it can be done at the site within few minutes. The significance of the three tests are as follows:- If a slump value is specified and the slump test give a significantly different value, this is an indication that the concrete should not be used. Additionally the shape of slump determines suitability of use since true slump is the most desired and a concrete with collapsed slump or zero should not be used.

- The compaction factor gives an idea about the workability of concrete and w/c ratio. Concrete mixes with too high or too low compaction factor should not be used because either their workability is too low (low w/c ratio) or they are highly susceptible to bleeding and segregation (high w/c ratio).

- Vee-Bee time test is a measure of workability. As for the other too tests, high Vee-bee value means unworkable concrete, and very low ones means that the concrete is highly susceptible to bleeding and segregation.

No comments: