Quantities Takeoff - BOQ, Cost estimation and Project planning and scheduling for construction project

Explanation of the project:

This project is Pharmaceutical Production building. According to the plans, areas can be summarized:

➧ Ground floor area = 729.57 m2

➧ Staircase area = 27.2 m2 Concrete strength and yielding strength of reinforcing steel:

For all bearing elements (Foundations, Tie Beams, Neck columns, Columns Slabs, Beams (dropped & hidden), Leveling Walls and Retaining walls) Concrete (B300)

fc’ = 250 Kg/m2

Yield strength of reinforcing steel for all bars

fy = 4200 Kg/cm2

Minimum concrete cover requirements for each structural member:

Columns: From side cover to face of stirrups 4.0 cm. Dimension of columns should be increased underground till the cover reach at least 5.0 cm from side of cover to face of stirrups. First stirrups start at 5cm from the face of foundations or slabs and to be continued through slab and foundation.

Beams: From side cover to face of stirrups 4.0 cm. First stirrups start at 5cm from the face of column.

Slabs: Top and bottom cover to face of steel 2.5 cm.

Bearing walls: From side cover to face of stirrups 2.5 cm.

Retaining walls: From external side cover (near soil) to face of stirrups 5.0 cm.

Plastic Spacers with variable sizes should be used to achieve the cover above.

For foundations:

➧ Bearing Capacity of soil is assumed to be ơE = 4 Kg/cm.

➧ Footing size is determined from the assumed bearing capacity of soil.

➧ Loose soil must be removed from foundation level.

➧ All foundations to be casted by concrete (B300) with a slump of 6”.

➧ Granular soil should be used for filling after foundations and also behind Retaining walls.

➧ The building is designed to carry five floors.

➧ Excavation for foundation must be done to reach a level according to the instructions of the engineer.

➧ Footing size is determined from the assumed bearing capacity of soil.

➧ Loose soil must be removed from foundation level.

➧ All foundations to be casted by concrete (B300) with a slump of 6”.

➧ Granular soil should be used for filling after foundations and also behind Retaining walls.

➧ The building is designed to carry five floors.

➧ Excavation for foundation must be done to reach a level according to the instructions of the engineer.

General notes:

➧ Concrete compression test should be taken for cast Concrete.

➧ External walls (behind stone) could be cast mechanically in site, and concrete should be tested. The result should be as shown in Material strength (above).

➧ Concrete for External walls (behind stone) should be tested (Compression Test), about three samples (minimum).

➧ All Bearing elements should be cast by using Ready mixed concrete with Pump.

➧ Vibrator should be used for all reinforced elements and also the Slope Screed on roof.

➧ Aggregates sizes should be less than (2cm)

➧ Formwork (metal scaffolding) only for slabs and drop beams

➧ External walls (behind stone) could be cast mechanically in site, and concrete should be tested. The result should be as shown in Material strength (above).

➧ Concrete for External walls (behind stone) should be tested (Compression Test), about three samples (minimum).

➧ All Bearing elements should be cast by using Ready mixed concrete with Pump.

➧ Vibrator should be used for all reinforced elements and also the Slope Screed on roof.

➧ Aggregates sizes should be less than (2cm)

➧ Formwork (metal scaffolding) only for slabs and drop beams

Quantities Takeoff

|

| Quantities takeoff and project management |

All quantities have been calculated according to CAD drawings, with specifications that mentioned above.

Footings

Table 1 – Quantities of footings

| FOOTINGS | ||||||

|---|---|---|---|---|---|---|

| No. of footings | Footing | Concrete of each type of footing (m3) | TOTAL blinding concrete (m3) | TOTAL insulation (m2) | TOTAL Concrete of footing (m3) | Excavation (m3) |

| 4 | F0 | 0.35 | 0.576 | 2.4 | 1.4 | 1.4 |

| 4 | F1 | 6.656 | 4.624 | 18.56 | 26.624 | 11.466 |

| 5 | F2 | 5.85 | 5.12 | 16.8 | 29.25 | 10.4 |

| 10 | F3 | 2.88 | 6.76 | 10.56 | 28.80 | 5.78 |

| 3 | F4 | 2.42 | 1.728 | 9.24 | 7.26 | 5.12 |

| 2 | F5 | 2.24 | 1.08 | 8.88 | 4.48 | 4.94 |

| 1 | F6 | 3.745 | 0.904 | 14.24 | 3.745 | 16.44 |

| TOTAL | 20.792 | 80.68 | 101.559 | 202.944 | ||

Sample calculation for Footing 1 (F1):

Length = 3.2 m

Width = 3.2 m

Height = 0.65 m

Concrete of one footing = 3.2*3.2*0.65 = 6.656 m3

Total blinding concrete = 3.4*3.4*0.1*4 = 4.624 m2

Total insulation = ((3.2*3.2)+4*3.2*0.65) = 18.56 m2

Note: Excavation should be with at least 50 cm from each side:

Total Excavation = 4.2*4.2*0.65 = 11.466 m3

Columns

Table 2 – Quantities of concrete for columns

| COLUMNS | |||

|---|---|---|---|

| Column type | surface area of columns (m2) | Long columns | Short columns |

| C1 | 0.36 | 2.2284 | 1.7316 |

| C2 | 0.24 | 1.1544 | |

| C3 | 0.18 | 1.1142 | 0.8658 |

| C4 | 0.33 | 1.5873 | |

| C5 | 0.24 | 1.1544 | |

| C6 | 0.22 | 1.0582 | |

| C7 | 0.21 | 1.0101 | |

| External wall | 2.172 | 9.1224 | |

| TOTAL concrete of columns (m3) | 46.7273 | ||

Sample calculation for Column 1 (C1) – Long :

Length = 0.6 m

Width = 0.6 m

Height = 6.19 m

Surface area = 0.6*0.6 = 0.36 m2

Concrete for one column = 0.36*6.19 = 2.2284 m3

There are 5 columns C1:

Total concrete for all columns = 5*2.2284 = 11.14 m3

Neck columns

Table 3 – Quantities for neck columns

| COLUMNS | |||

|---|---|---|---|

| Column type | surface area of neck columns (m2) | Concrete of neck columns (m3) | insulation (m2) |

| C1 | 0.4225 | 0.2535 | 1.56 |

| C2 | 0.2975 | 0.1785 | 1.44 |

| C3 | 0.2275 | 0.1365 | 1.2 |

| C4 | 0.4025 | 0.2415 | 1.8 |

| C5 | 0.2925 | 0.1755 | 1.32 |

| C6 | 0.2875 | 0.1725 | 1.68 |

| C7 | 0.2625 | 0.1575 | 1.32 |

| TOTAL (m3) | 1.3155 | 10.32 | |

Sample calculation for Neck Column 1 (C1):

Length = 0.65 m

Width = 0.65 m

Height = 0.6 m

Surface area = 0.65*0.65 = 0.4225 m2

Concrete for one neck column = 0. 65*0.65*0.6 = 0.2535 m3

Insulation for one neck column = 0.65*0.6*4 = 1.56 m2

There are 5 neck columns C1:

Total concrete for all 5 neck columns C1 = 5*0.2535 = 1.27 m3

Total insulation for all 5 neck columns C1 = 5*1.56 = 7.8 m3

Tie Beams

Table 4 – Quantities for Tie Beams

| Tie Beams | |||

|---|---|---|---|

| - | Concrete (m3) | Blinding concrete (m3) | insulation (m2) |

| TOTAL | 46.1945 | 13.86 | 321.48 |

All volumes have been obtained from AutoCAD drawings directly

Concrete for all tie beams (two types) = 40.412+5.7825 = 46.1945 m3

Blinding concrete for all tie beams = 12.16+1.7 = 13.86 m3

Insulation = 283.63+37.85 = 321.48 m2

Slab on grade

Table 5 – Quantities for slab on grade

| Slab on grade | ||

|---|---|---|

| - | Concrete (m3) | insulation (m2) |

| TOTAL | 68.31 | 13.07 |

Sample calculation for slab on grade:

Surface area = 683.1 m2

Parameter = 130.7 m

Thickness = 10 cm

Concrete = 683.1 * 0.1 = 68.31 m3

Insulation = 130.7*0.1 = 13.07 m2

Beams

Table 6– Quantities for beams

| BEAMS | |

|---|---|

| BEAM | Concrete (m3) |

| B1+B2 | 41.328 |

| B3 | 0.891 |

| B4 | 1.22175 |

| B5 | 0 |

| B6 | 6.012 |

| B7 | 2.358 |

| B8 | 2.952 |

| B9 | 1.8306 |

| B10 | 0 |

| B11 | 0 |

| B12 | 0 |

| B13 | 2.4225 |

| B14 | 0 |

| TOTAL | 59.01585 |

Note: Concrete has been calculated just for the drop part, because the other part has been calculated with the slab

Sample calculation for beam 3 (B3), as I mentioned just for the drop part:

Length = 6.6 m

Width = 0.3 m

Height = 0.45 m

There is just one B3:

Total concrete for B3= 6.6*0.3*0.45 = 0.891 m3

Wall footing for the staircase

Table 7– Quantities for wall-footings

| Footings of staircase (contains the elevator) | |||

|---|---|---|---|

| Type of wall-footing | Concrete of each type of footing (m3) | TOTAL blinding concrete (m3) | insulation (m2) |

| wf1 | 3.744 | 1.092 | 11.8 |

| wf2 | 1.24 | 0.372 | 5.98 |

| wf3 | 1.176 | 0.336 | 4.62 |

| combined | 4.352 | 1.224 | 14.32 |

| TOTAL | 10.512 | 3.024 | 36.72 |

Sample calculation for wall footing 1 (WF1):

Length = 7.8 m

Width = 1.2 m

Height = 0.4 m

There is just one WF1:

Total concrete for WF1= 0.4*1.2*7.8 = 3.744 m3

Total blinding concrete for WF1= 1.4*7.8*0.1= 1.092 m3

Area of insulation has been obtained from AutoCAD directly = 9.36+2.44 = 11.8 m2

Walls under the ground for the staircase

Table 8– Quantities for walls under the ground

| walls under the ground (for the staircase) | |||

|---|---|---|---|

| - | Concrete (m3) | Hollow blocks (m2) | insulation (m2) |

| wf1 | 2.62875 | 0 | 21.405 |

| wf2 | 1.2 | 0 | 9.975 |

| wf3 | 9 | 0 | 9.375 |

| combined | 3.6 | 14.4 | 14.4 |

| TOTAL | 16.42875 | 14.4 | 55.155 |

Sample calculation for wall 1 of the part which is under the ground (WF1):

Length = 7.01 m

Thickness = 0.25 m

Height = 1.5 m

There is just one WF1:

Total concrete for WF1= 1.5*.25*7.01 = 2.62875 m3

Hollow blocks for WF1= 0 m3

Area of insulation = (0.25*1.5)+(1.5*7.01*2)= 21.405 m2

Shear walls above the ground (contains slabs for each floor and concrete of staircase)

Table 9– Quantities for Shear walls above the ground and slab for each floor

| shear walls above the ground & slaps of each floor | |

|---|---|

| - | Concrete (m3) |

| wf1 | 13.319 |

| wf2 | 6.08 |

| wf3 | 45.6 |

| combined | 17.593125 |

| slabs and stairs | 18.14 |

| TOTAL | 100.732125 |

Sample calculation for wall 1 of the part which is above the ground (WF1):

Length = 7.01 m

Thickness = 0.25 m

Height = 1.5 m

There is just one WF1:

Total concrete for WF1= 7.6*.25*7.01 = 13.319 m3

For slabs and staircase volume of concrete has been obtained directly from autocad:

Concrete for slabs and stairs = 2.74+2.35+4.15+2.35+1.26+5.29 m3

Quantities of steel - sample calculations

Table 10– Quantities of steel for footing 4 F4

| foundation 4 | |||||

|---|---|---|---|---|---|

| - | L.B.L | L.B.T | L.T.L | L.T.T | Weight of bars (ton) |

| Bars | 12 | 12 | 1 | 1 | |

| Φ16 | 2.9 | 2.9 | 0.113448 | ||

| Φ10 | 2.7 | 2.7 | 0.003402 | ||

| Sum | 0.11685 | ||||

Table 11– Quantities of steel for column 4 C4

| foundation 4 | |||||

|---|---|---|---|---|---|

| - | L.B.L | L.B.T | L.T.L | L.T.T | Weight of bars (ton) |

| Bars | 12 | 12 | 1 | 1 | |

| 16 | 2.9 | 2.9 | 0.113448 | ||

| 10 | 2.7 | 2.7 | 0.003402 | ||

| Sum | 0.11685 | ||||

Sample calculation for Neck Column 4:

Table 12– Quantities of steel for Neck Column 4

| Main Reinforcement | Stirrup | |||||||

|---|---|---|---|---|---|---|---|---|

| #of bars | length | unit weight | Total Weight | #of bars | length | unit weight | Total Weight | |

| 16 | 18*2=36 | 3.65 | 1.63 | 0.214 | ||||

| 14 | ||||||||

| 10 | ||||||||

| 8 | 68 | 2.16 | 0.41 | 0.06 | ||||

Sample calculation for Beam 5:

Table 13– Quantities of steel for Beam 5

| Beam5 | |||||

|---|---|---|---|---|---|

| # of bars | Length | unit weight | area | total Weight | |

| 14 | 10 | 3.2 | 0.00125 | 0.00015386 | 0.04 |

| 16 | |||||

| Total Weight | 0.04 | ||||

Sample calculation for shear wall 2:

Table 14– Quantities of steel for shear wall 2

| Shear Wall 2 | |||||||

|---|---|---|---|---|---|---|---|

| Longitudinal | Transverse | ||||||

| #of bars | length | unit weight | total weight | #of bars | length | total weight | |

| 16 | 1.63 | ||||||

| 14 | 1.25 | ||||||

| 18 | 2.07 | ||||||

| 10 | 0.63 | ||||||

| 12 | 32 | 10 | 0.92 | 294.4 | 92 | 3.2 | 0.2709 |

Sample calculations for formwork quantities

Thickness = 15 cm

Parameter = 24.2 m

Surface area = 27.18 m

Formwork = 27.18+24.2*0.15= 30.81 m2

Shuttering for column 4 (C4):

Length = 0.6 m

Width = 0.6 m

Height = 6.19 m

Surface area = 0.6*0.6 = 0.36 m2

Shuttering for one column = 0. 6*6.19*4 = 14.86 m2

There are 5 columns C1:

Total concrete for all columns = 5*14.86 = 74.28 m2

Note: All formwork quantities have been obtained directly from the surface area give from the AutoCAD.

Cost estimate

Microsoft Excel has been used for this purposeTable 16– Activities productivity

| Activity | Productivity | Crew | Labor Cost/day |

|---|---|---|---|

| Shuttering | 30 m2/day | 1 General+1 Skilled | - $ |

| Steel Fixing (footings, shear walls...) | 600 kg/day | 1 General+1 Skilled | - $ |

| Steel Fixing (Slabs) | 1000 kg/day | 1 General+1 Skilled | - $ |

| Concrete Pouring | 140 m3/day | 3 General | - $ |

| De-shuttering | 40 m2/day | 1 General | - $ |

| Insulation (two faces) | 25 m2/day | 1 General | - $ |

| Blocks | 30 m2/day | 1 General | - $ |

| Scaffolding installation | 30 No./day | 1 General | - $ |

| Excavation to reduce level including Backfilling | 88 m3/day | Subcontractor | - $ |

| Excavation for foundations including Backfilling and working space | 44 m3/day | Subcontractor | - $ |

| building block partitions | 100 m2/day | 1 General+1 Skilled | - $ |

| stone building | 30 m2/day | 1 General+1 Skilled | - $ |

| blocks behind stone | 9 m2/day | 1 General | - $ |

| concrete boring behind stone | 120 m3/day | 1 General | - $ |

| stone cladding | 35 m2/day | 1 General+1 Skilled | - $ |

| vertical plastering | 20 m2/day | 1 General+1 Skilled | - $ |

| horizontal plastering | 18 m2/day | 1 General+1 Skilled | - $ |

| vertical painting | 35 m2/day | 1 General+1 Skilled | - $ |

| horizontal painting | 35 m2/day | 1 General+1 Skilled | - $ |

| false ceiling | 35 m2/day | Subcontractor | lump-sum per m2 |

| roof | 250 m2/day | 1 General+1 Skilled | - $ |

| Tiling ( Marble) | 30 m2/day | Subcontractor | lump-sum per m2 |

| Tiling ( porcelain) | 25 m2/day | Subcontractor | lump-sum per m2 |

| Tiling ( ceramic ) | 25 m2/day | Subcontractor | lump-sum per m2 |

Table 17– Materials unit cost

| Material | Unit | Cost $/unit | Notes |

|---|---|---|---|

| Concrete B300 | m3 | -$ | Including arriving to the site and pumping |

| Concrete B200 | m3 | -$ | Including arriving to the site and pumping |

| Steel | ton | -$ | Including fabrication, +$X to include lifting to higher level |

| Wood | m3 | -$ | Including arriving to the site |

| Nito proof | bucket | -$ | +$X to include Brush for each pocket |

| Nylon | m2 | -$ | |

| Jack | No. | -$ | Renting for 25 days |

| Basecourse | m2 | -$ | Including compaction |

Project planning and scheduling

Primavera software has been used for planning. Also, for this chapter we're going just to preview some examples.Bill of quantities BOQ

You can download the original sample from the project documents in the end of the article

|

| BOQ |

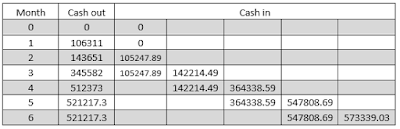

Overdraft calculation

You can download the original sample from the project documents in the end of the article

S-Curve

Project schedule

Project documents to download:

BOQ Sample - Click here to download

Overdraft Calculation & S-Curve Sample - Click here to download

Project schedule Sample - Click here to download

No comments: